About Columbine

Located in northern Colorado, Columbine Precision Machining is a single source manufacturing; production machine shop facility, offering high quality metal and plastic parts to companies in northern Colorado since 1982.

Our mission is to exceed expectations through excellent quality, communication and on-time delivery. We strive to be a problem-free supplier, so you can keep your customers happy.

Latest Addition to Columbine

20mm Bar Fed Swiss Lathe

ProShop ERP System Coming Soon

EXPERIENCE

Columbine Precision Machining has been in business since 1982. With over 70 combined years of experience in the machining industry, we are confident we are able to not only meet your needs, but exceed them. Some industry experience would include, but not limited to: heavy equipment, electronics, plumbing, irrigation, medical, robotics, construction.

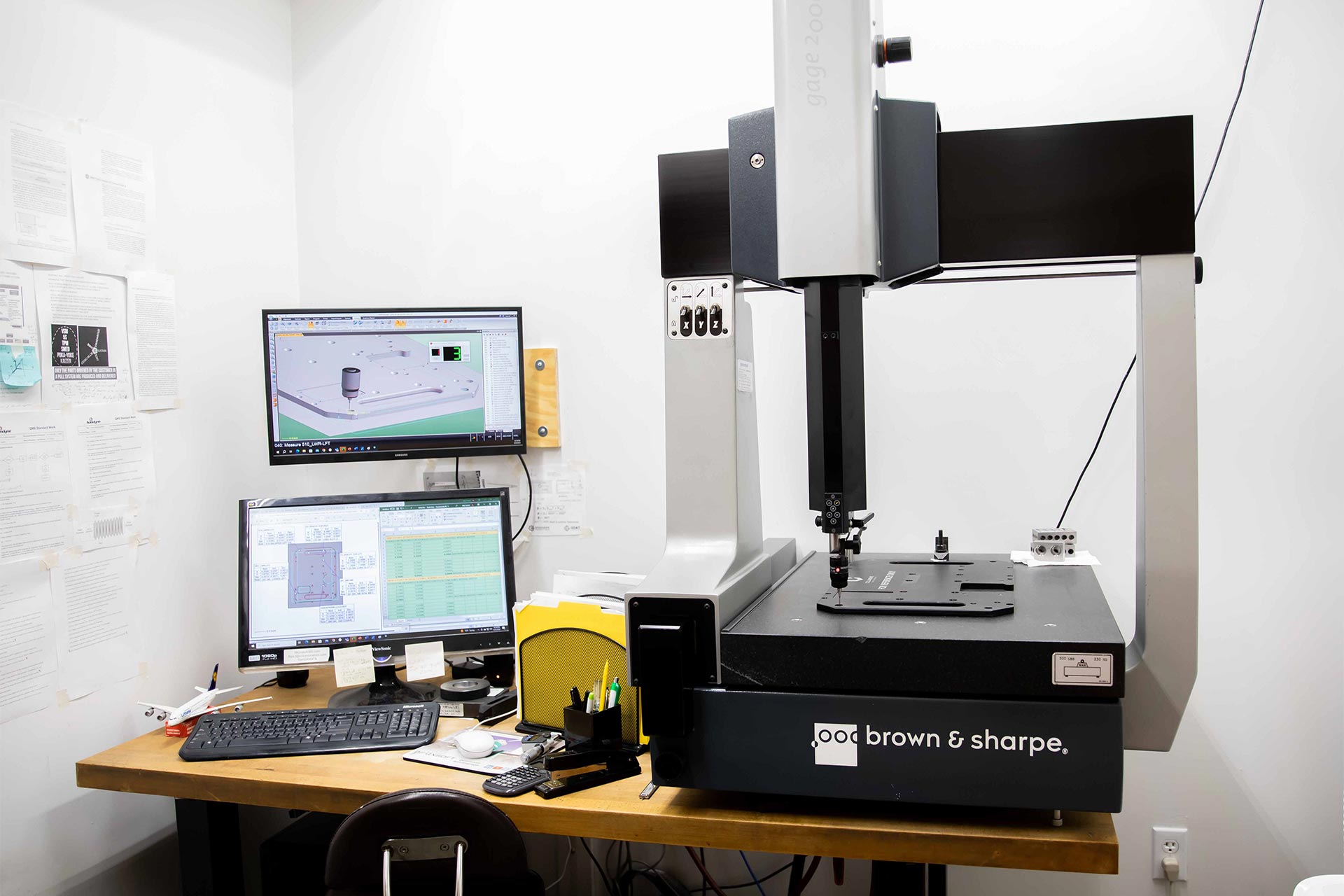

QUALITY

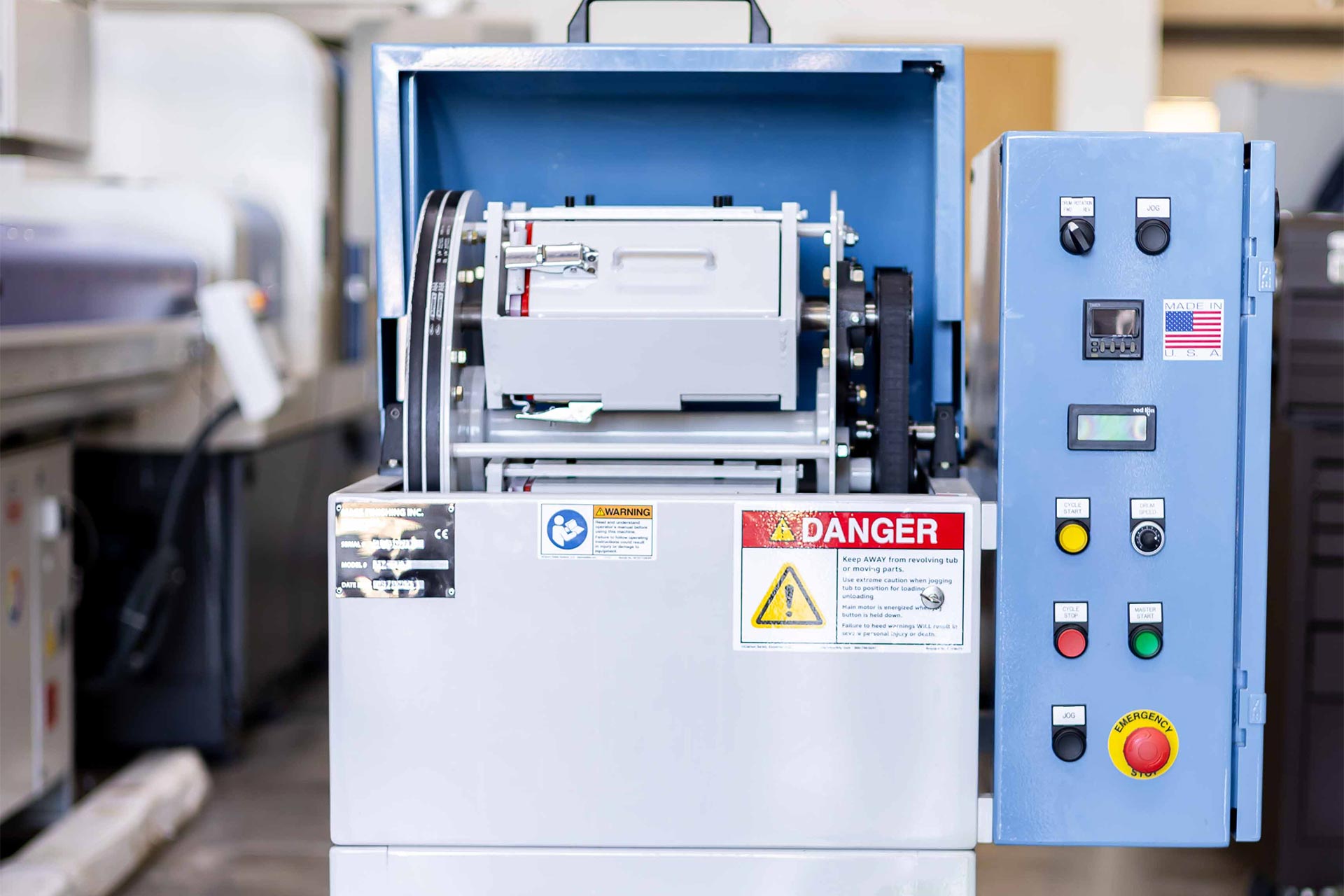

The quality in our business starts with great communication. From there we use some of the finest equipment on the market to produce a high quality product that is right the first time. We pride ourselves on our on-time deliveries and our low return percentages.

RELIABILITY

Reliability is a trait that we believe is extremely important, but not commonly seen in most of the machine shops in this industry. We are honest, trustworthy, dependable and authentic. Whether it’s a rush job, or a complicated long run, you can count on us.

PRECISION

In a machine shop, precision is everything. The term “close enough” doesn’t cut it in a machine shop, and certainly not in ours. We use high quality machines and inspection equipment to make sure we do everything we can to provide you a qualified product.

VERSATILITY

With our vast experience in the industry, we are able to be extremely versatile. Whether it’s a simple part, or a complicated high volume production machining run, we can make it happen.

PERSONABLE

Our full team meets on a daily basis to communicate the needs for that day, and the days to come. We are easy to get a hold of either by phone or email, and you will always be able to talk to the same person.

Meet The Executive Team

Wes Allbritten

Jerad Allbritten

Full Team

Full Team

Our Services

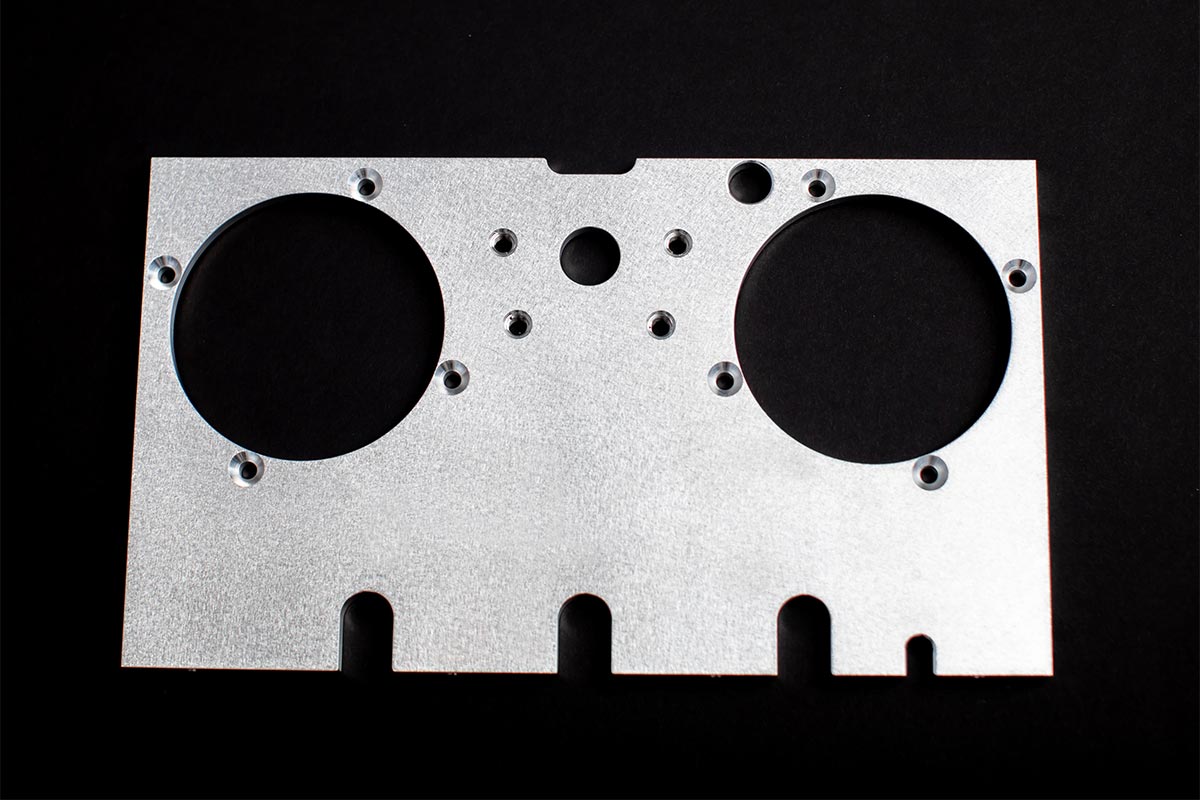

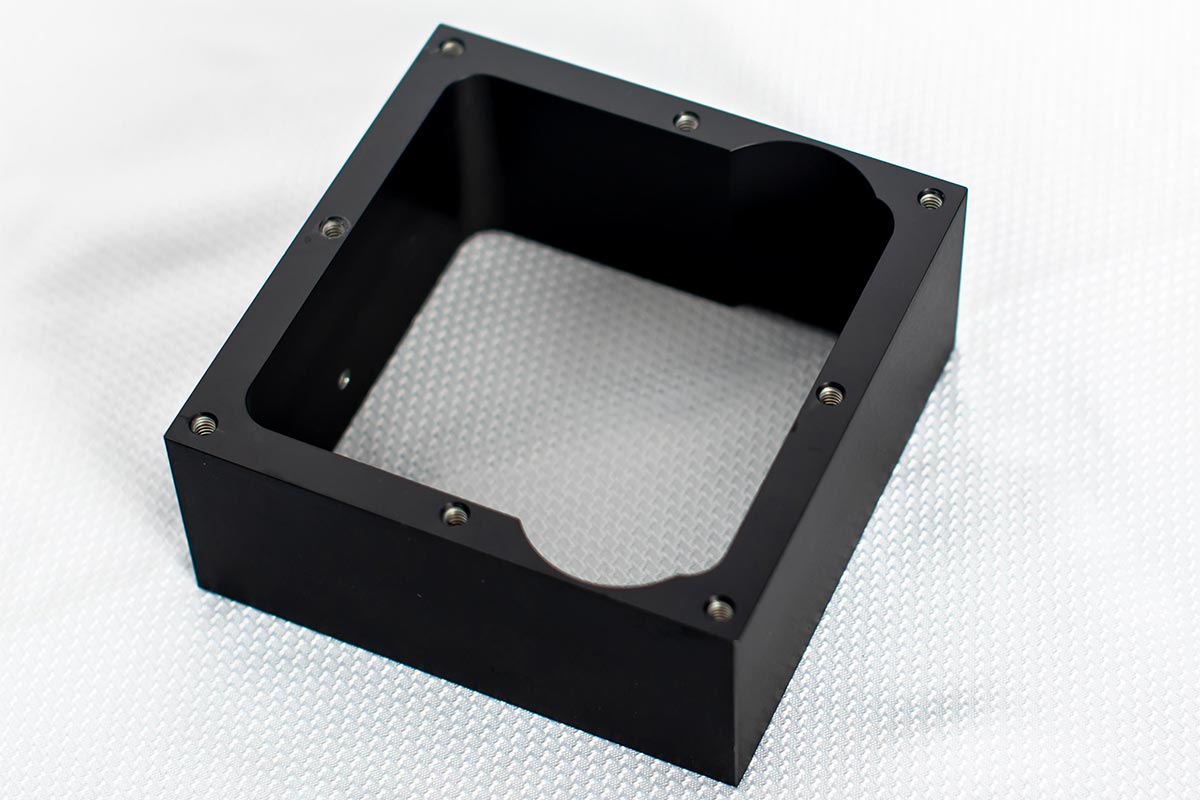

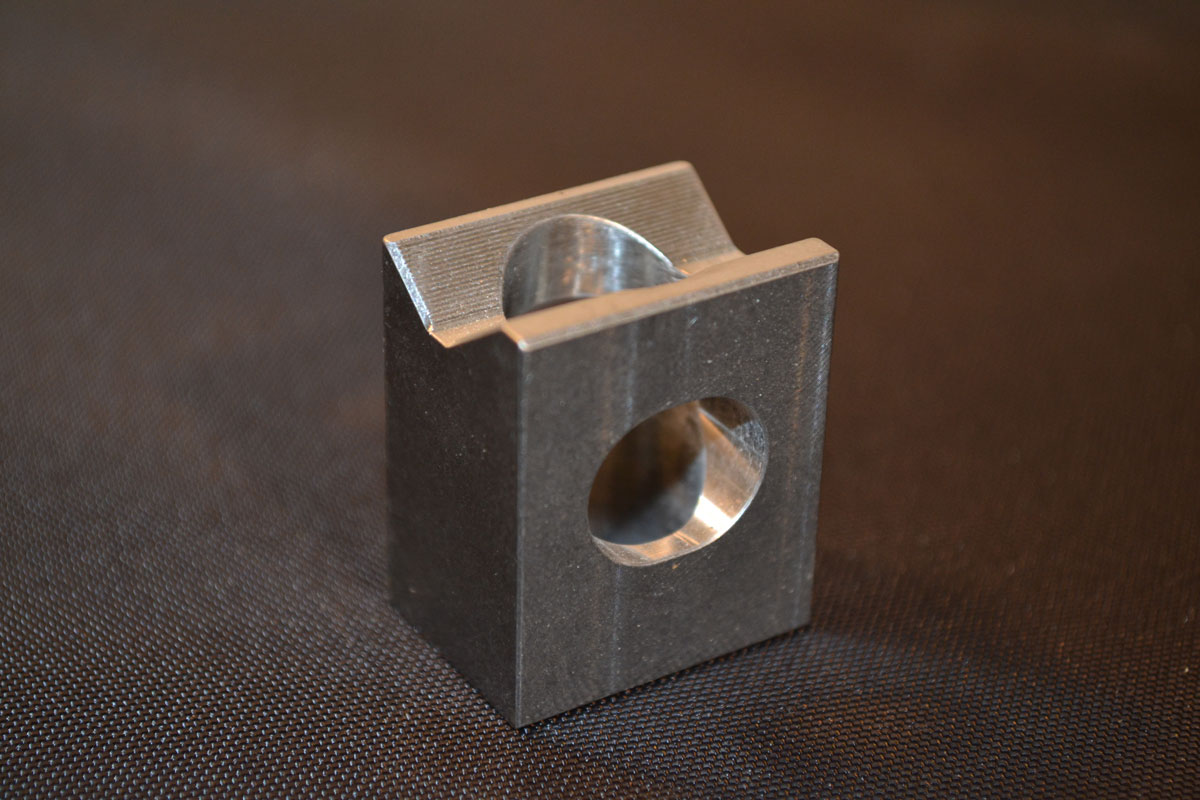

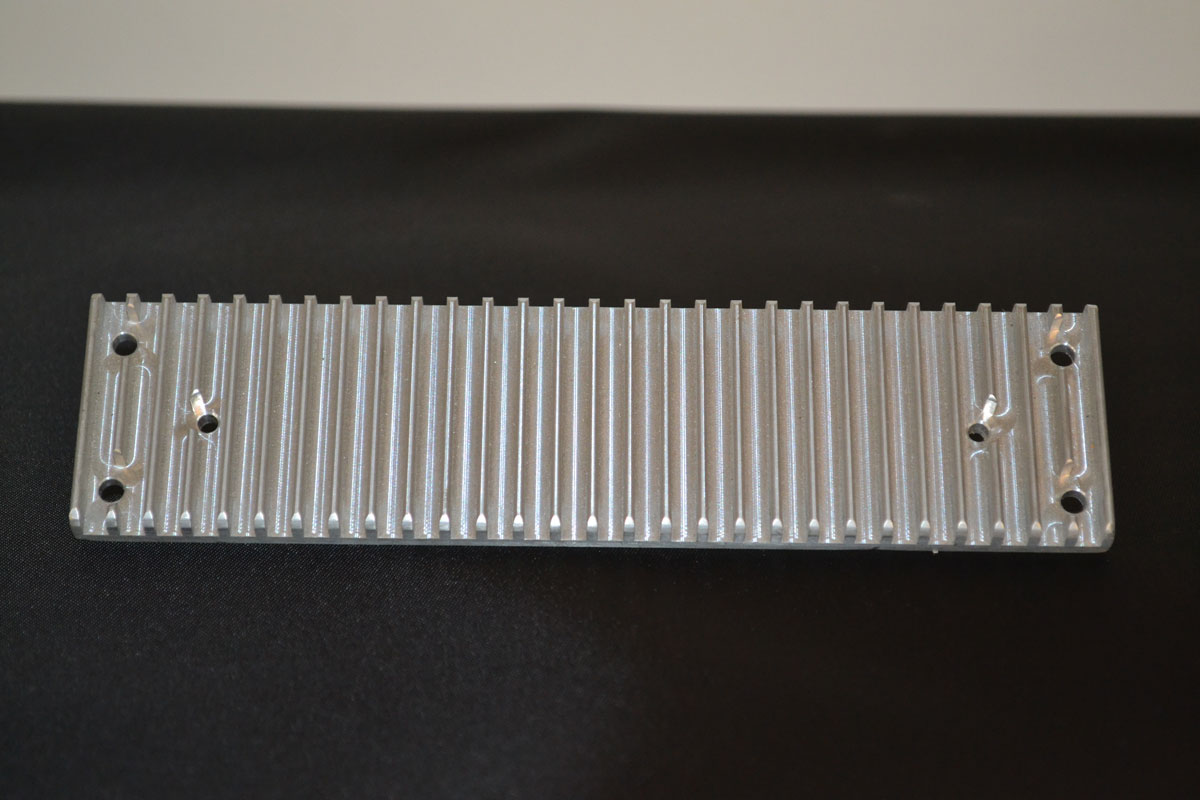

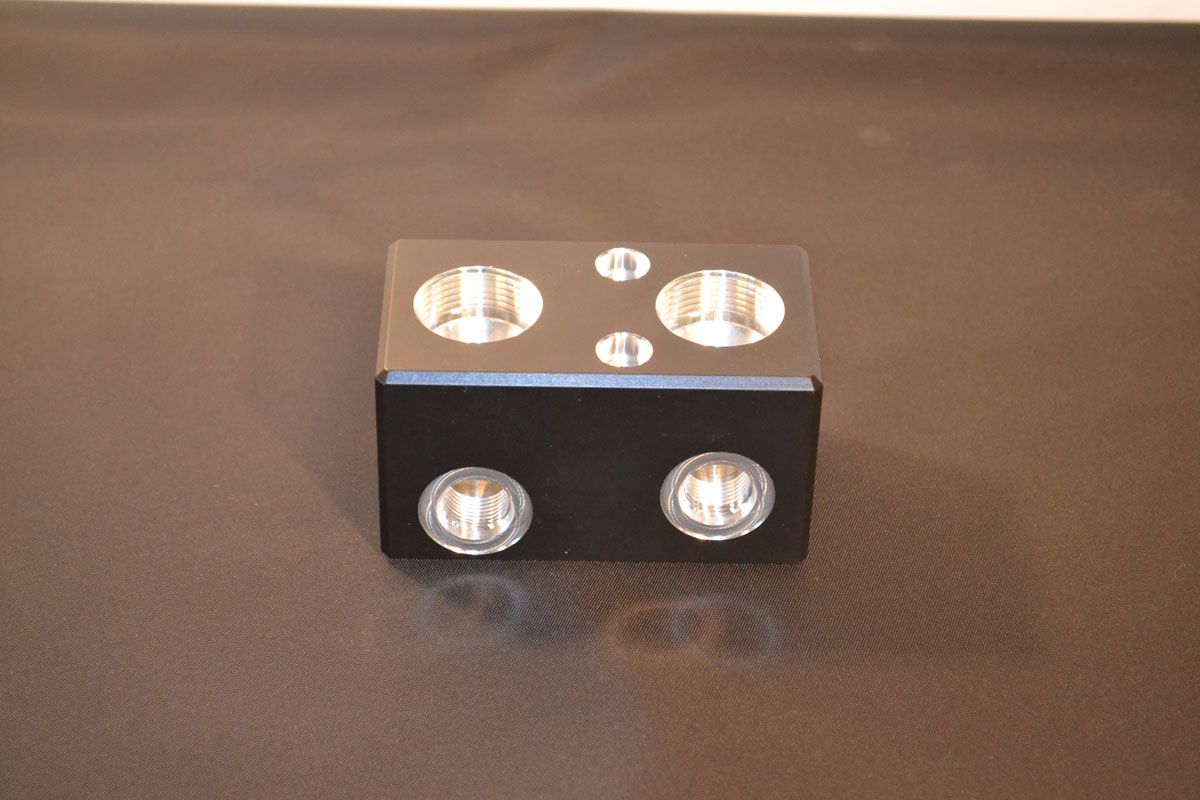

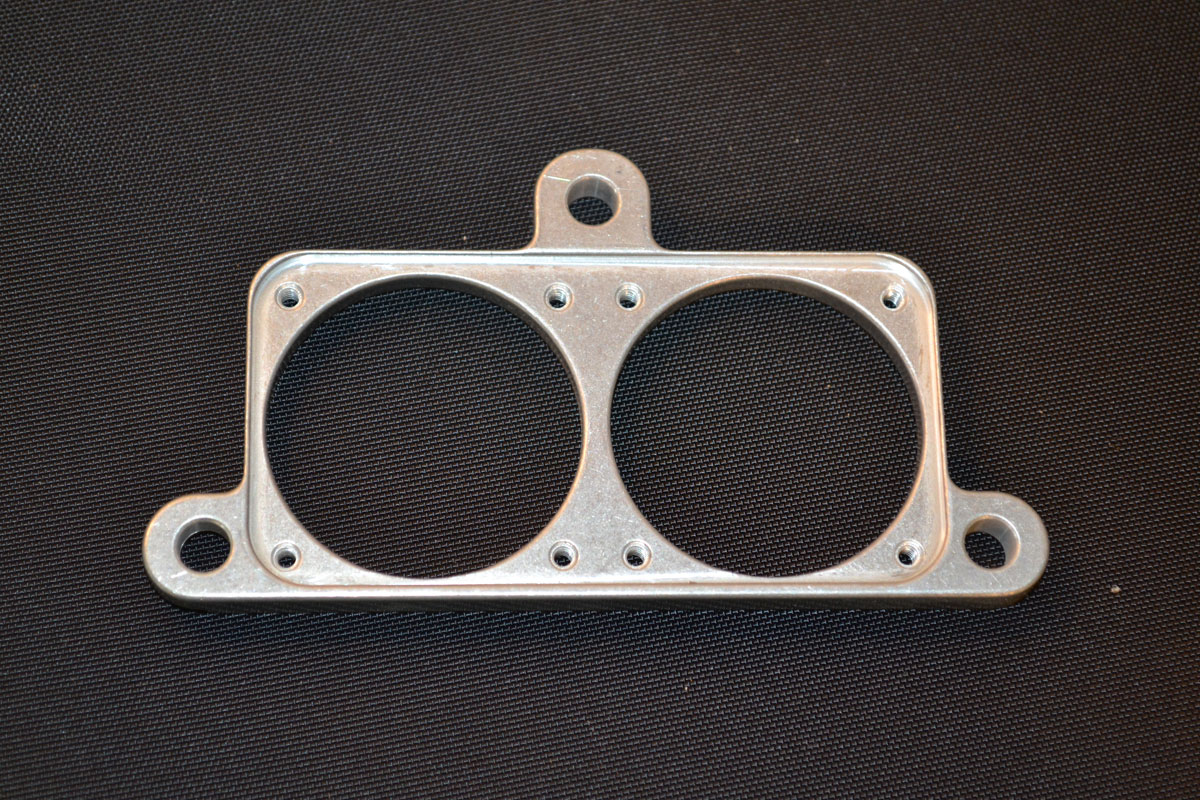

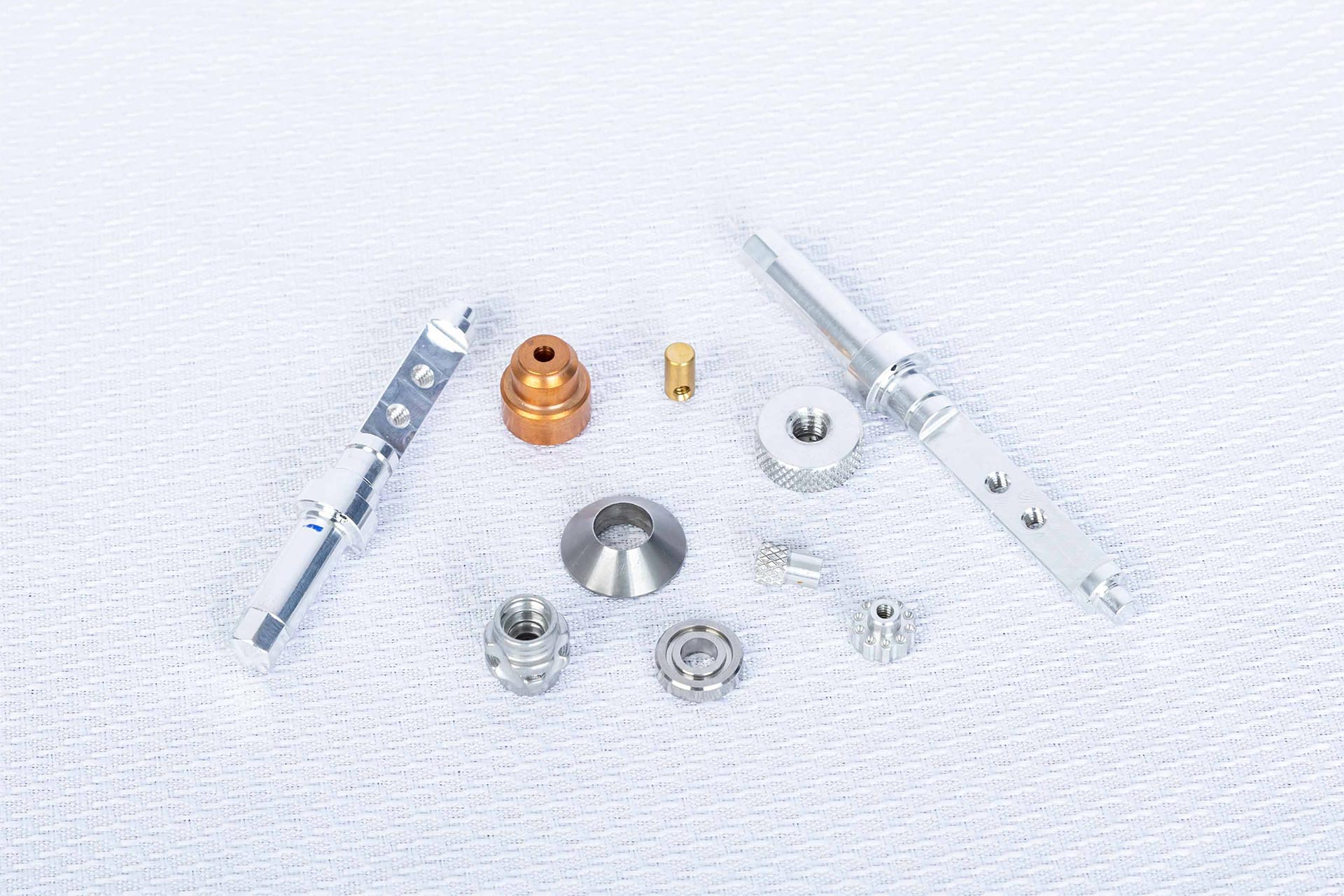

Production Machining

Custom production machining of parts for a wide range of applications including machinery and specialty parts.

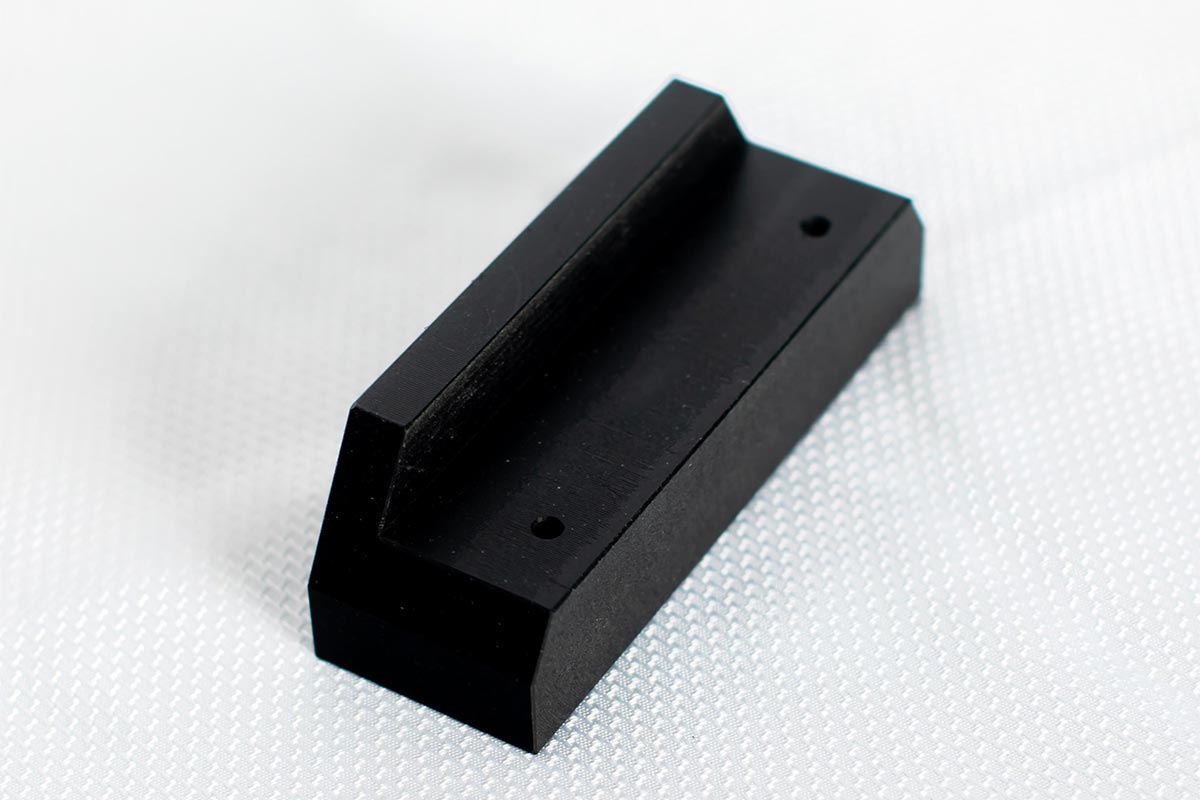

Production Tooling

Making jigs and fixtures that allows your company to run more efficiently and effectively.

Prototypes, Product Design & Development

Immense knowledge allows us to be a great resource for design and development. We can be the first tangible step in your great idea.

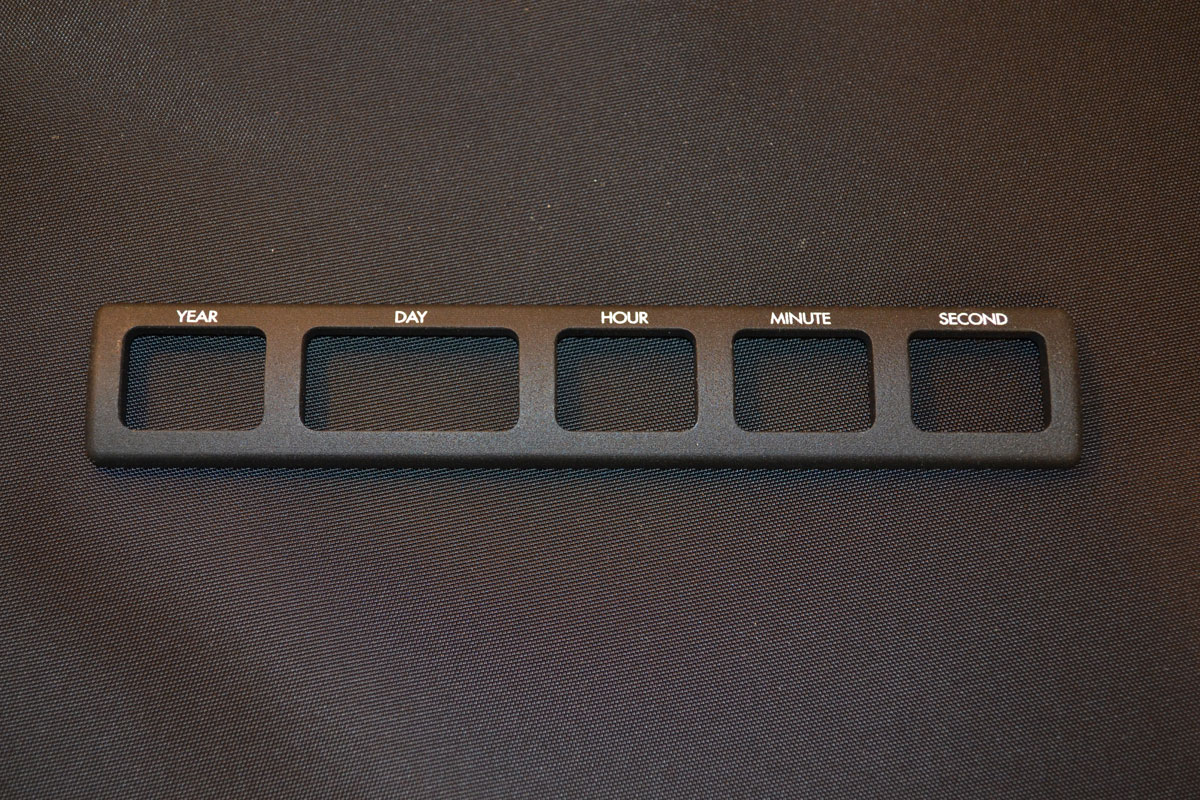

Inspection/Production Fixtures

Enhances your CMM accuracy for higher quality parts.

Plating, Heat Treating, & Laser Engraving

We offer industrial plating, rinsing, heat treating, laser engraving, tumbling and deburring.

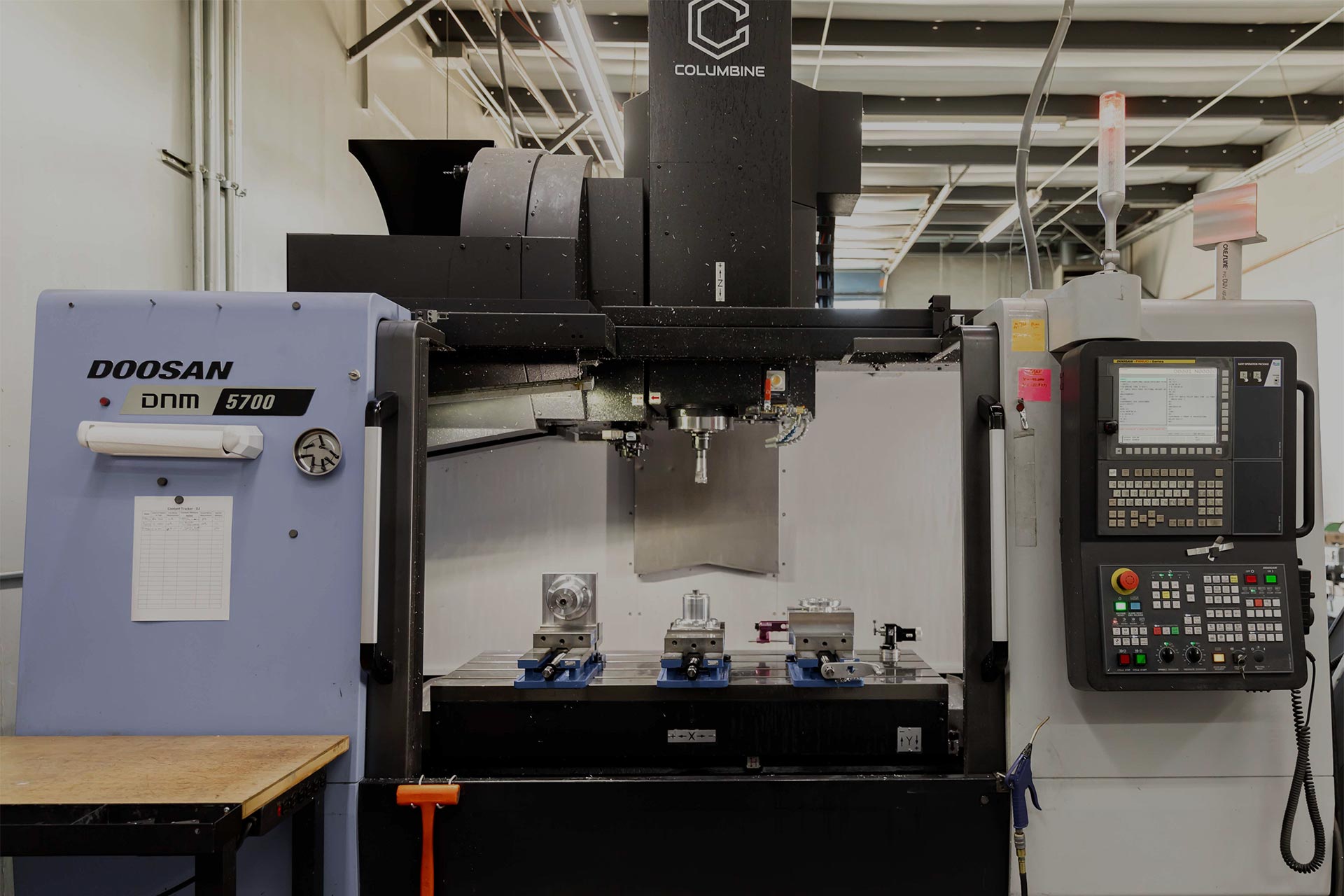

CNC Milling

4 vertical CNC mills, and a trunnion for positional 5 axis milling capabilities.

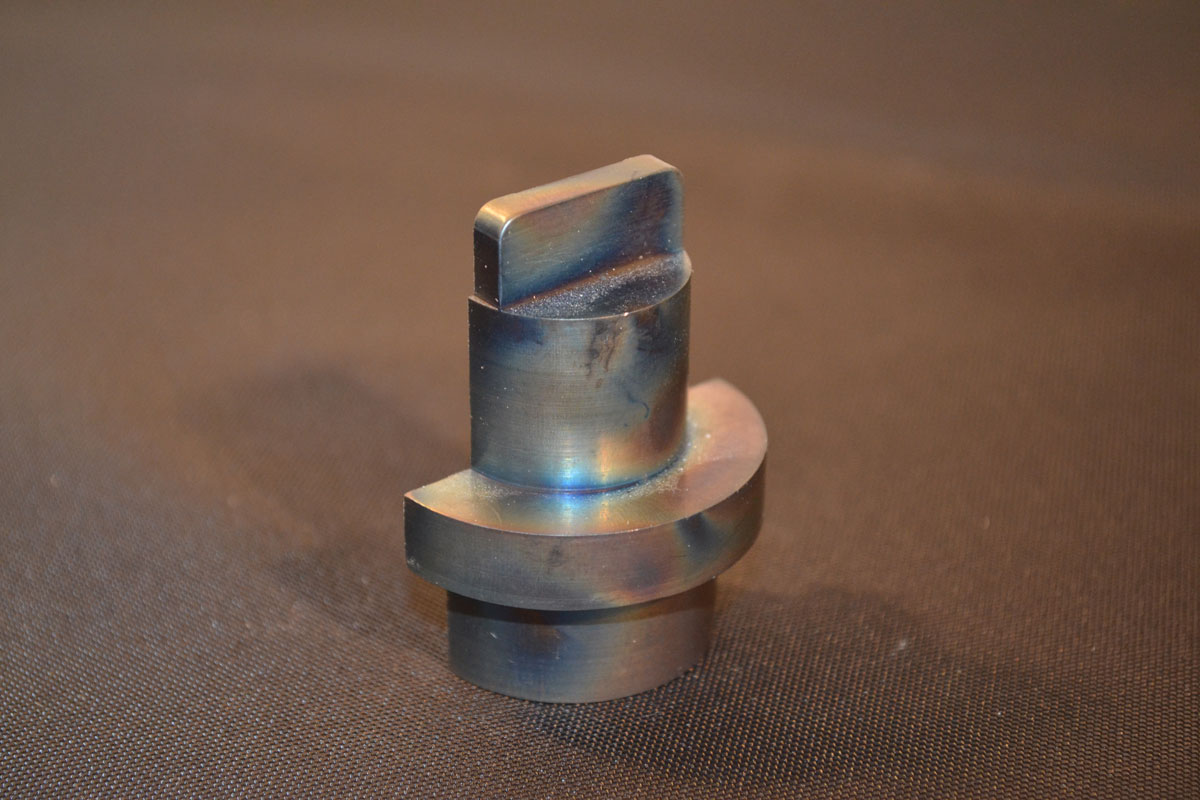

CNC Turning

Hardinge turning center with 2” thru spindle, and 8” chuck capabilities

Certification

Certification available for material and all outside processes we offer.

Swiss Machining

Nomura swiss 20mm lathe for high volume production runs.

Recent Works

Precision. Quality. Reliability

Like what you see?

Contact us to find out more about our precision machining services.

Machines & Equipment

Hi tech equipment to ensure quality and precision